-

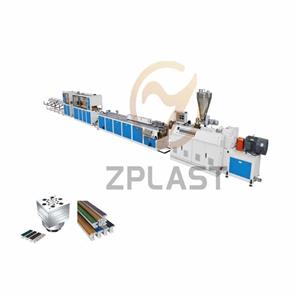

upvc window profile door profile extrusion line

pvc profile production line is mainly for producing PVC window profile,according to different profile section and mould to choose different conical or parallel twin-screw extruder and provide relative vaccum sizing tank,haul-off ,cutter,stacker and auxiliary equipment.

Send Email Details -

UPVC window profile extrusion line machine

Our PVC profile extrusion line is mainly used to produce PVC window profile, PVC door frame profile, window sill, door plate, PVC folding door, PVC wide board, PVC gutter, PVC fence, multi-holes pipe (four holes, six holes, seven holes, nine holes), PVC cable trunking profile, PVC corners, PVC trims, WPC profiles, PVC ceiling panel, PVC wall panel, and other plastic profiles. Extrusion capacity varies with different extruder models. According to different products, we can you SJZ series conical twin screw extruder or SJP series parallel twin screw extruder. For down stream equipment, we can choose among YF108, YF180, YF240, YF300, YF400, YF600, YF800, YF1000 and YF1200

Send Email Details -

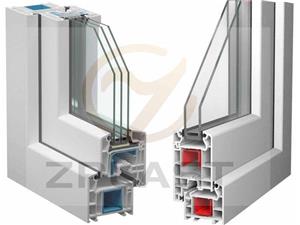

pvc wall panel pvc fence profiles extrusion mould company manufacturer

Mould NamePlastic PVC WPC Doors Mould Company Material of Mould3Cr17 Nimo or Germiny Din 1.2316 Mould ComponentDie Head + Calibrator + Water Tank + Heating Plates Mould Cavity1 Surface TreamentMirror Polished + Chrome Plated Profile MaterialWPC, UPVC, PVC Extrusion Speed2 or 3 meters per minute TestingMould will be tested before leave factory PackageWood/Polywood case (standard export packing) Lead Time30 days after contracted

Send Email Details -

WPC profile plastic extrusion mould company factory manufacturer

1,Nearly 1500 sets of mould making experience every year, by constant inprovement,our moulds are adapted to various formulas and equipment. 2,Excellent processing equipment and advanced manufacturing craft guarantee the precision. 3,The shaping model cavity adopts carving of wire cutting,so the flatness of the visible surface of thye product is higher. 4,Specially made fastnener protection device

Send Email Details