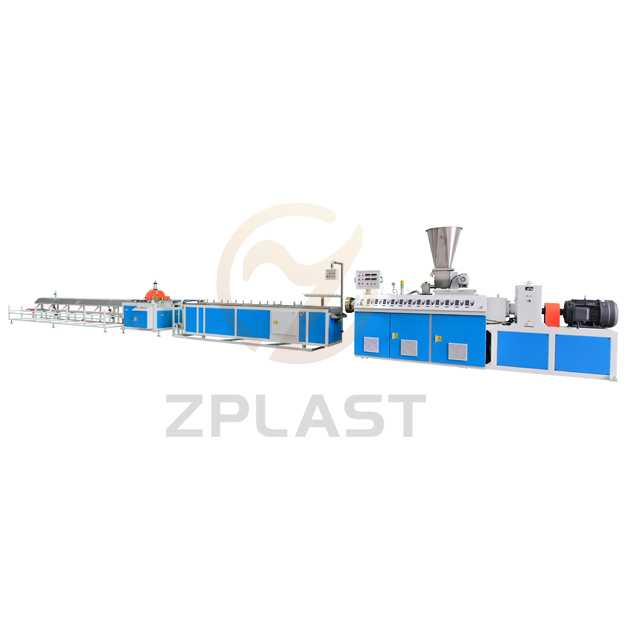

PE&PP Wood Plastic Profile Extrusion Line

Brand ZHUOTIAN

Product origin Shanghai

Delivery time 40-45

Now our wpc extruders keeps innovation, we use three extruder or five extruder coextrusion technology , to give perfect surface pattern effect.

Download

PE wood-plastic-profile-extrusion-line

Technicial Parameter

| Model | YF108 | YF180 | YF240 | YF300 | YF400 |

| Max. profile width | 108 | 180 | 240 | 300 | 400 |

| Haul of width | 150 | 150 | 150 | 150 | 150 |

| Haul of speed | 6 | 5 | 5 | 5 | 5 |

| Total power(without extruder) | 10 | 19 | 28 | 31 | 35 |

1. The WPC floor making machine can be used to produce wpc decking floor, fence, gazebo, benches, trash cans, etc.

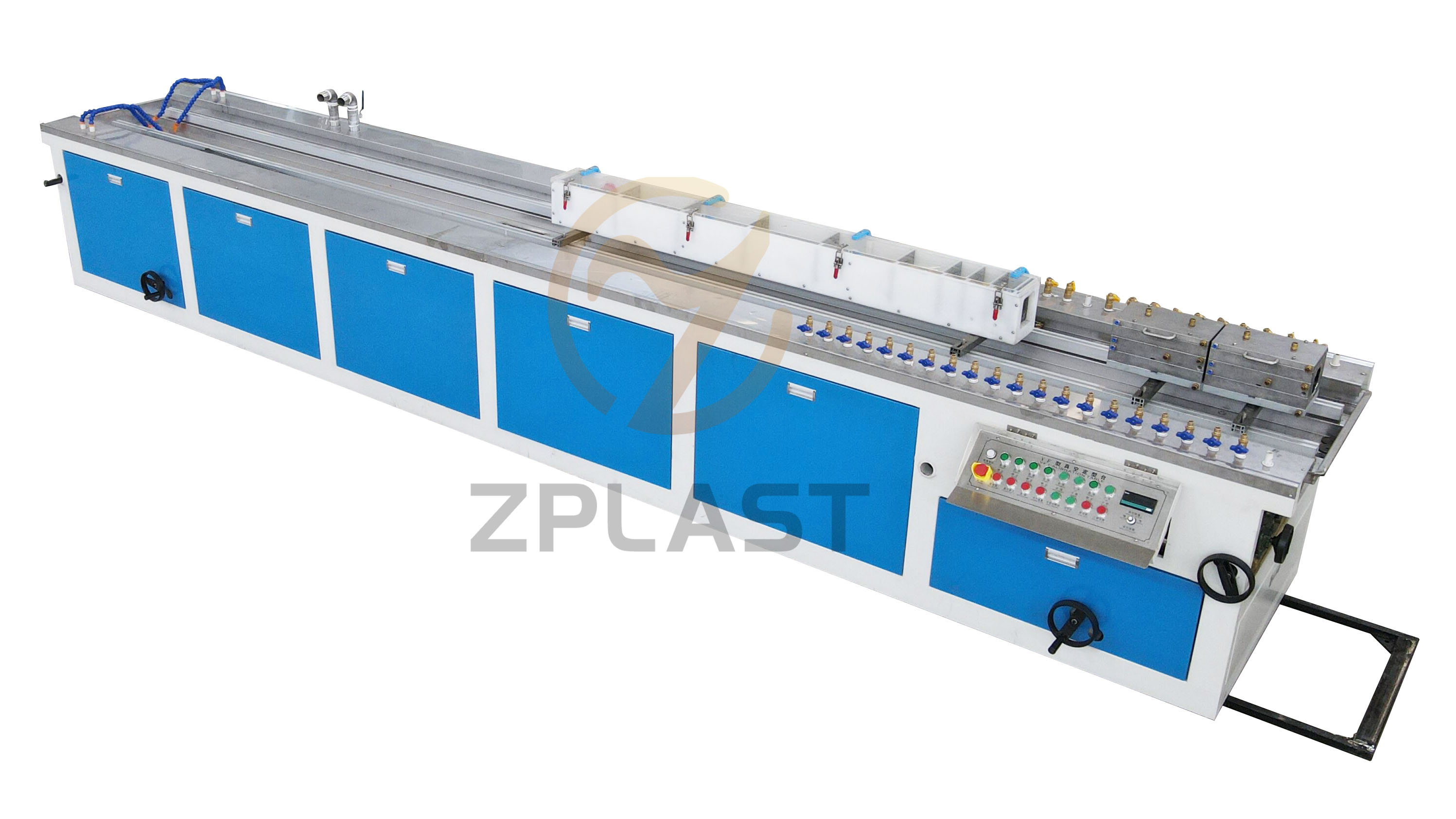

2. The WPC floor making machine mainly consists of a screw feeder, a SJSZ65/132 conical twin-screw extruder, moulds, a vacuum setting table, a cutting machine, a stacker.

3. By changing different moulds, the same production line can be used to produce WPC profiles。

Our Services

Our main design and manufacturing softwares are Auto CAD, CAE,SOLIDWORKS(3D),etc.We are able to accept and deal with files as dwg,dxf,x-t and so on .

When customer send offer of order, we will immediately reply within 24 hours, as meet customer's requirement.

Value-added services

Comprehensive cost control service;

Mould designing service;

Emergency manufacturing delivery service:;

Mold debugging Service;

Customer production training service;

High Quality After-Sale Service

· Provide technical support

· One year free quality warranty

·Lifetime paid maintenance