Plastic Pe Wpc Decking Coextrusion Mould

Brand ZHUORAN

Product origin Huangshi

Delivery time 25-35 days

Supply capacity 100-150sets/month

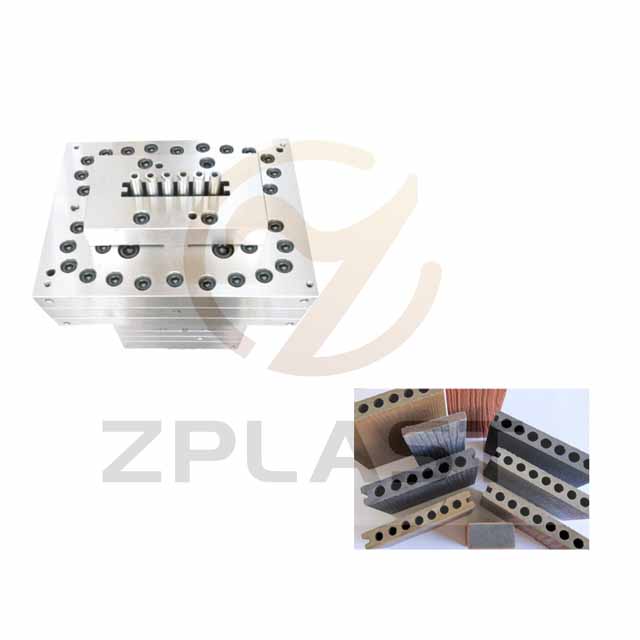

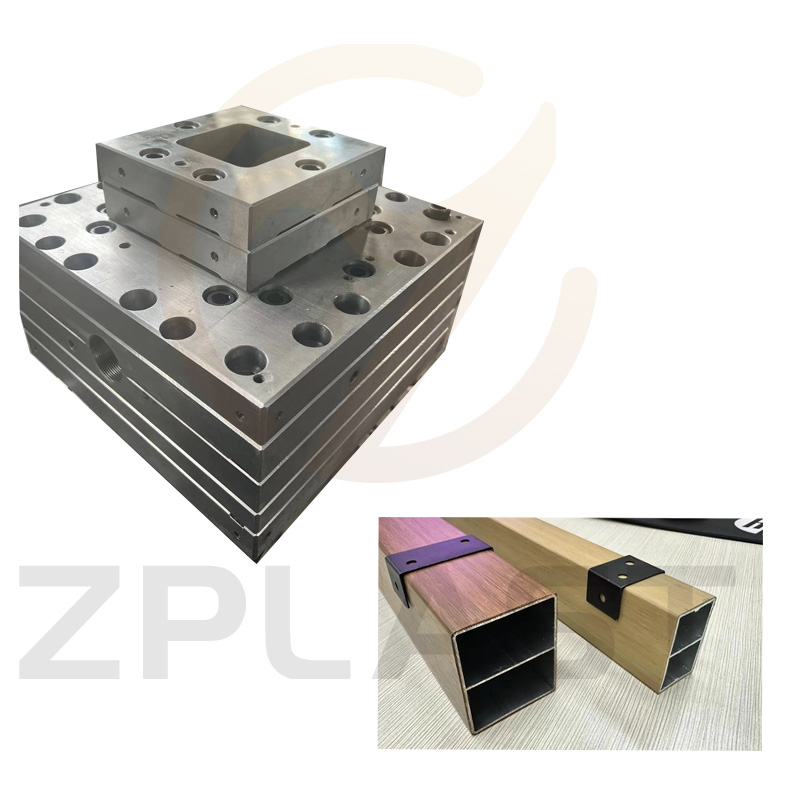

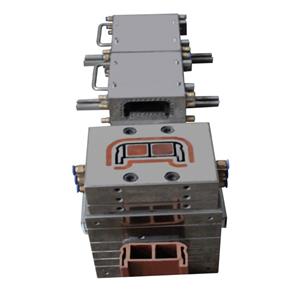

1. The coextrusion decking can be with round hole,square hole and solid design.

2. Coextrusion material: ASA and modified PE

3. Co-extruder: can be SJ35 and 45

4. Reasonable air and water design for mould head , which help profile cool better.

Shaping Mode: Extrusion Mould

Mould Material: 3cr17 and 3cr13 and Din1.2316,

Wear parts, use special material with hardening treatment

Product Name: Plastic Pe Wpc Decking CoExtrusion Mould

Cavity: One or Mulity cavity

Surface treatment: mirror polishing

H.S code: 8480790090

Processing center: CNC milling

OEM: Acceptable

Extrusion mould construction: Die head+calibrator+water tank+heating plates(aluminum or steel heating plate optional)

Package: Polywood case

Our Advantage:

1.Rich experience in designing and producing plastic extrusion mould,advanced technology and perfect mould quality which is most competitive

2.The mould material is treated specially which is to length the produce life.

3.Our mould are processing by auto-cnc milling center which is to ensure high precision of mould size,

4.We can design the mould structure according to customer’s formula.

5.Mould cavity data and reasonable water and air configuration which can ensure the customer produce best quality and quantity final profile.

6.Our mould is suitable for different formula and equipment to produce.