Plastic Pvc Casement Window Extrusion Mould

Brand ZHUORAN

Product origin Huanggshi

Delivery time 25-35 working days

Supply capacity 100-150 sets/month

1. High speed vertex water tank to make each angle of the products to get even and enough cooling to reduce (utmost) the bending probability of products which happens due to interior stress.

2. Precise flowing control,stable output

3. Taper Aligning pins, Quality Guarantee

Advantage of Zhuoran Mould

1.Rich experience in designing and producing plastic extrusion mould,advanced technology and perfect mould quality which is most competitive.

2.The mould material is processed specially which is to length the lifetime.

3.Our mould are processing by auto-cnc milling center which is to ensure high precision of mould size,

4.We can design the mould structure according to customer’s formula.

5.Mould cavity data and reasonable water and air configuration which can ensure the customer produce best quality and quantity final profile.

6.Our mould is suitable for different formula and equipment to produce

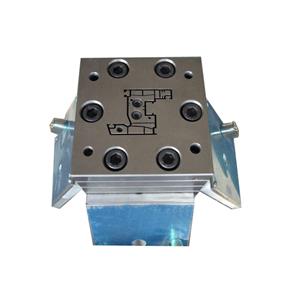

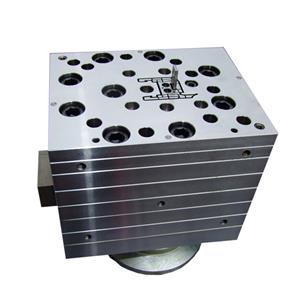

Shaping Mode: Extrusion Mould

Mould Material: 3cr17 and 3cr13 and Din1.2316,

Wear parts, use special material with hardening treatment

Product Name: Plastic Pvc Casement Window Extrusion Mould

Cavity: One or Mulity cavity

Surface treatment: mirror polishing

H.S code: 8480790090

Processing center: CNC milling

OEM: Acceptable

Extrusion mould construction: Die head+calibrator+water tank+heating plates(aluminum or steel heating plate optional)

Package: Polywood case

Inside Feature of Our Die Head

1. Water cooling through mandril can cool the inner cavity thoroughly, the inner cavity could be smooth and regular, and there will be no swelling taking place. The section view of profile is very regular and good looking. (Air cooling or natural cooling will make the inner cavity liable to swell and make the inner rib uneven).

2.The water flow in the mandril can be controlled by valve, and make the products' inner cavity and outer wall cool synchronously, thus improve the inherent quality such as anti impact strength, meanwhile improve the stability of products' quality in the production.

3. The cooling efficiency outperforms air cooling and natural cooling countpart so the product extrusion speed can be improved greatly.

Company profile

1. the biggest WPC extrusion mould designer and manufacturer.

2. We are the only one mould factory who attend the People's Republic of China National wood plastic composite flooring Standards drafting .

3. We are the Professional Committee of WPC products governing unit.

Our clients:

Domestic market:

· New Tech Wood,Kind Wood

· AnhuiSentai New Material,

· NanjingJufeng Advanced Materials,

· Shenzhen GEM High-tech Co., Ltd,

· Huangshan Huasu New Materials Science & Technologyetc

Foreign market:

Southeast Asia Market Middle East Market, ,Turkey ,Russia, ect.