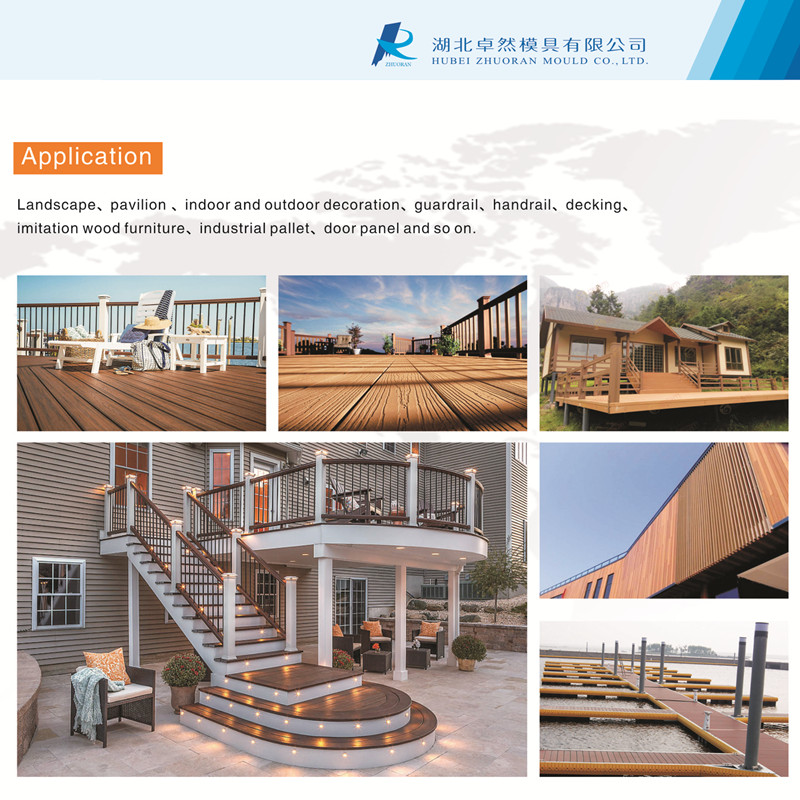

Wpc Decking Extrusion Mold Manufacturer In China

Brand ZHUORAN

Product origin Huanggshi

Delivery time 25-35 working days

Supply capacity 100-150sets/month

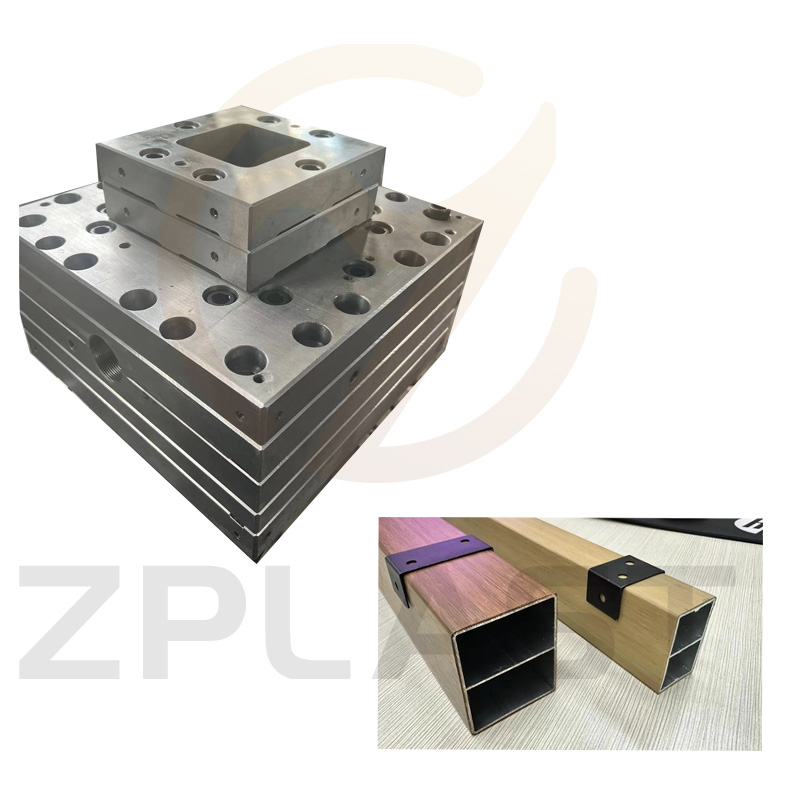

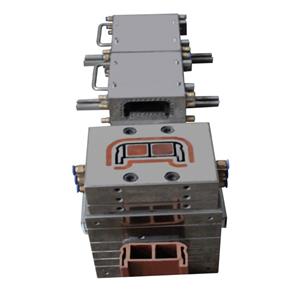

1. The coextrusion decking can be with round hole,square hole and solid design.

2. Coextrusion material: ASA and modified PE

3. Co-extruder: can be SJ35 and 45

4. Reasonable air and water design for mould head , which help profile cool better.

Wpc decking extrusion mold manufacturer in china

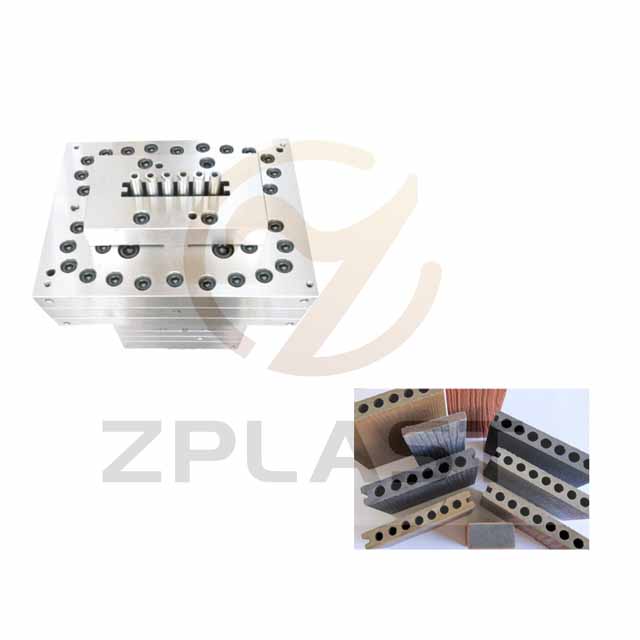

Mould Head Features:

1. Can be quick assembling as die plates with straight pins.

2. Scientific cavity design and polished channel to ensure smooth extrusion and higher extrusion speed.

3. High quality hard chrome plating 3Cr17 nimo / Din1.2316 mould steel.

4. Experienced technicians and precision equipments ensure the tolerance accuracy of the mould.

5. Scientific designed extrusion channel.

Calibrator Features:

1. Calibrator is designed with inside and outside double circulating water cooling system to shape the profile quickly.

2. Mirror polished channel to ensure the profile with smooth surface.

3. Use pure copper nozzles, it is durable and user friendly.

4. U-shaped handle for easier operation.

5. Centerline adjustment screw.

6. Mould material has been specially treated, which is to extend the service life.

Water Tank Features:

1. High-quality vacuum negative pressure water tank with high-strength PMMA board combined with stainless steel plate edging.

2. The main advantages of the water tank are good cooling effect, uniform cooling and accurate forming dimensions.