-

Plastic HDPE Aluminum Coextrusion Project

1.First plastic aluminum coextrusion mold manufacturer in china 2.Have exported project to USA and European market 3.With rich experience and perfect after sale service

Send Email Details -

Plastic Pvc Foaming Ceiling Panel Profile Extrusion Mould

Mould Head Features: 1. Can be quick assembling as die plates with straight pins. 2. Scientific cavity design and polished channel to ensure smooth extrusion and higher extrusion speed. 3. High quality hard chrome plating 3Cr17 nimo / Din1.2316 mould steel. 4. Experienced technicians and precision equipments ensure the tolerance accuracy of the mould. 5. Scientific designed extrusion channel.

Send Email Details -

Hot

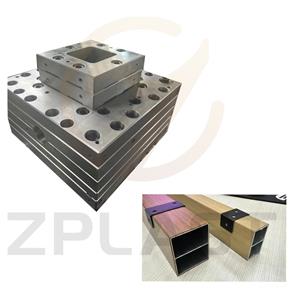

Plastic Pe Wpc Beam Extrusion Mould

1.Design the mould structure according to the customer’s formula. 2. Professional and reasonable water and air configuration can ensure the customer produce best quality products 3. Suitable for different formula and equipment

Send Email Details -

Wpc Coextrusion Embossing Decking Extrusion Mould/tool/die

Indoor and outdoor decoration. Mould Material has been specially treated. Which is to extend the service life. Mould head is designed with inside and outside double circulating water cooling system to shape the profile quickly.

Send Email Details -

Pvc Sheet Piles Extrusion Molds

C Plastic Flood Protection Stopper Extrusion Tooling Mould details Products material: UPVC Products size: customerized size could be ordered Mould steel : 3Cr17 or negotiable Delivery time: 35 days Calibrators: normally length 260mm* 3 sets depend on the profile design and wall thickness water tank: length 2000mm, vaucuum depend on profile design Testing samples for acceptance before shipment formulation and operation Engineer services could be offered

Send Email Details -

Plastic Pe Wpc Wall Cladding Extrusion Mould

1. Preland plates and mandril of mould head will be treated specially,the hardness and lifetime will be better and longer 2. Output:200-350ton 3. Steady production Inside Feature of Our Die Head 1. Water cooling through mandril can cool the inner cavity thoroughly, the inner cavity could be smooth and regular, and there will be no swelling taking place. The section view of profile is very regular and good looking. (Air cooling or natural cooling will make the inner cavity liable to swell and make the inner rib uneven). 2.The water flow in the mandril can be controlled by valve, and make the products' inner cavity and outer wall cool synchronously, thus improve the inherent quality such as anti impact strength, meanwhile improve the stability of products' quality in the production. 3. The cooling efficiency outperforms air cooling and natural cooling countpart so the product extrusion speed can be improved greatly.

Send Email Details -

Wood Plasic Composite Decking Extrusion Mold

Material: WPC - Indoor and outdoor decoration, such like decking, flooring, wall panel - High extrusion speed - Easy to use and replace - Long-term - Can be repaired - Mould Material has been specially treated. Which is to extend the service life. - Mould head is designed with inside and outside double circulating water cooling system to shape the profile quickly.

Send Email Details -

Wood Plastic Composite Coextrusion Decking Mold

- Material: WPC - Indoor and outdoor decoration, such like decking, flooring, wall panel - High extrusion speed - Easy to use and replace - Long-term - Can be repaired - Mould Material has been specially treated. Which is to extend the service life. - Mould head is designed with inside and outside double circulating water cooling system to shape the profile quickly.

Send Email Details