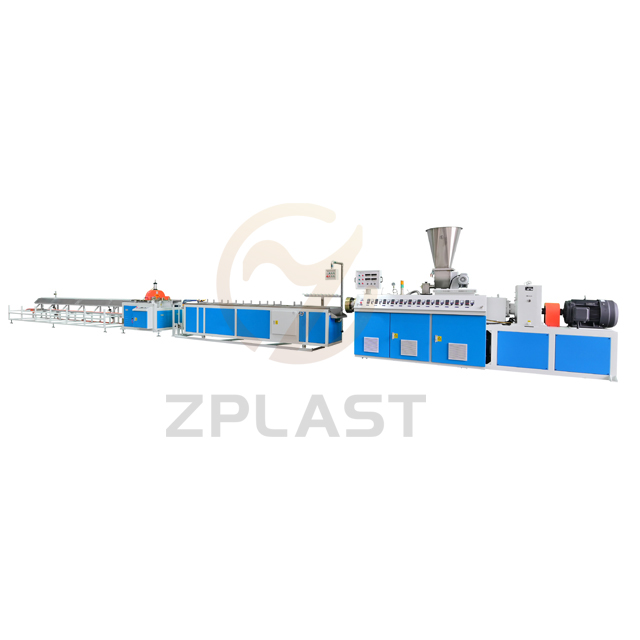

50/25 Single Screw Extruder

Brand ZHUORAN

Product origin huangshi

Delivery time 60workdays

Supply capacity 60 set/year

1. the single extrusion Line can be used to produce small plastic profile. for example ABS and PC etc,

2. the single extrusion Line mainly consists of a screw feeder, a conical twin-screw extruder, moulds, a vacuum setting table, a cutting machine, a stacker and some auxiliary machine (optional)

3. By changing different moulds, the same production line can be used to produce plastic profile with different size

work condition:

power: 3-phase, 380v+/- 10%, 50HZ

total power: <100 kw

cooling water:< 20°C ,0.2~0.4 Mpa, ~3T/h

compressed air: 0.4~0.6 Mpa

specification :

A.SJSZ50/25 SINGLE SCREW EXTRUDER

1 | Extrusion System (Screw & Barrel)

| L:D | 25:1 |

Screw diameter | ¢50mm | ||

Capacity | 30~40kg/h | ||

Screw material

| alloy steel of high quality – 38CrMoAlA, nitrogen treatment, with the thickness: 0.5~0.7mm, the surface hardness: HV740~940. | ||

Barrel material

| alloy steel of high quality – 38CrMoAlA, nitrogen treatment, with the thickness: 0.6~0.7mm, the surface hardness ≥HV940. | ||

| gear box body material: | HT 200 | ||

| gear box material | 20CrMnTi | ||

Heating zone quantity

| 4 with total power 30kw Temperature range: 50~300℃ | ||

Blower fan power | 0.18kw/set (3sets) | ||

Quality guarantee for screw & barrel

| Advanced processor, inspection machine, strict heat treatment, supplying testing report, guarantee 10000 hours of screw and barrel under normal operation. | ||

2 | Feeding System

| With stainless steal hopper | |

Dosing feeding system | |||

Feeding motor power

| 0.55kw, 3-phase asynchronous motor; Rotation speed of motor: 10 ~1500 r/min; Rotation speed of feeding screw: 1 ~ 50 r/min. | ||