Plastic PVC Polymer Profile Extrusion Machines And Extruders

Brand ZHUOTIAN

Product origin Shanghai

Delivery time 50-60

Supply capacity 30set/month

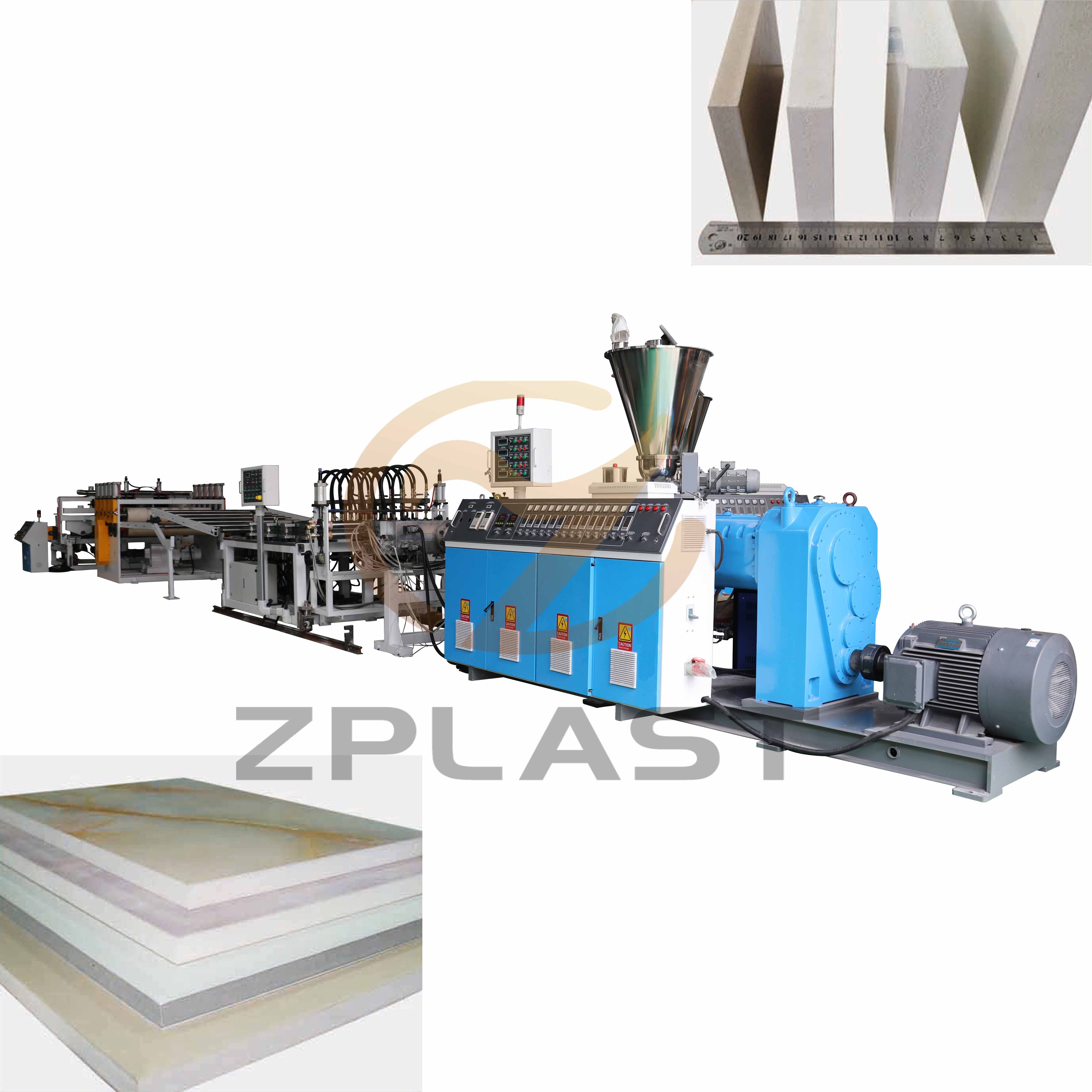

The extrusion method of plastic extruder and plastic extrusion machines refers to melting the plastic at a high temperature of about 200 degrees, and then the molten plastic is formed into the desired shape when it passes through the mold.

Plastic PVC Polymer Profile Extrusion Machines And Extruders

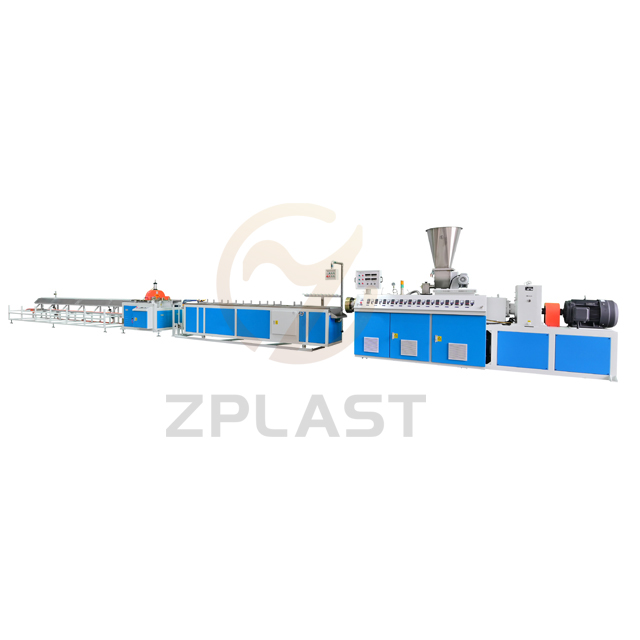

1. List of plastic extruders( For 65/132):

NO. | Name | Qty. |

1 | Conical twin screw extruder(include the spial loader) | 1set |

2 | Vacuum calibration table | 1set |

3 | Haul-off unit (seperate type) | 1set |

4 | No-dust cutter (seperate type) | 1set |

5 | Stacker | 1set |

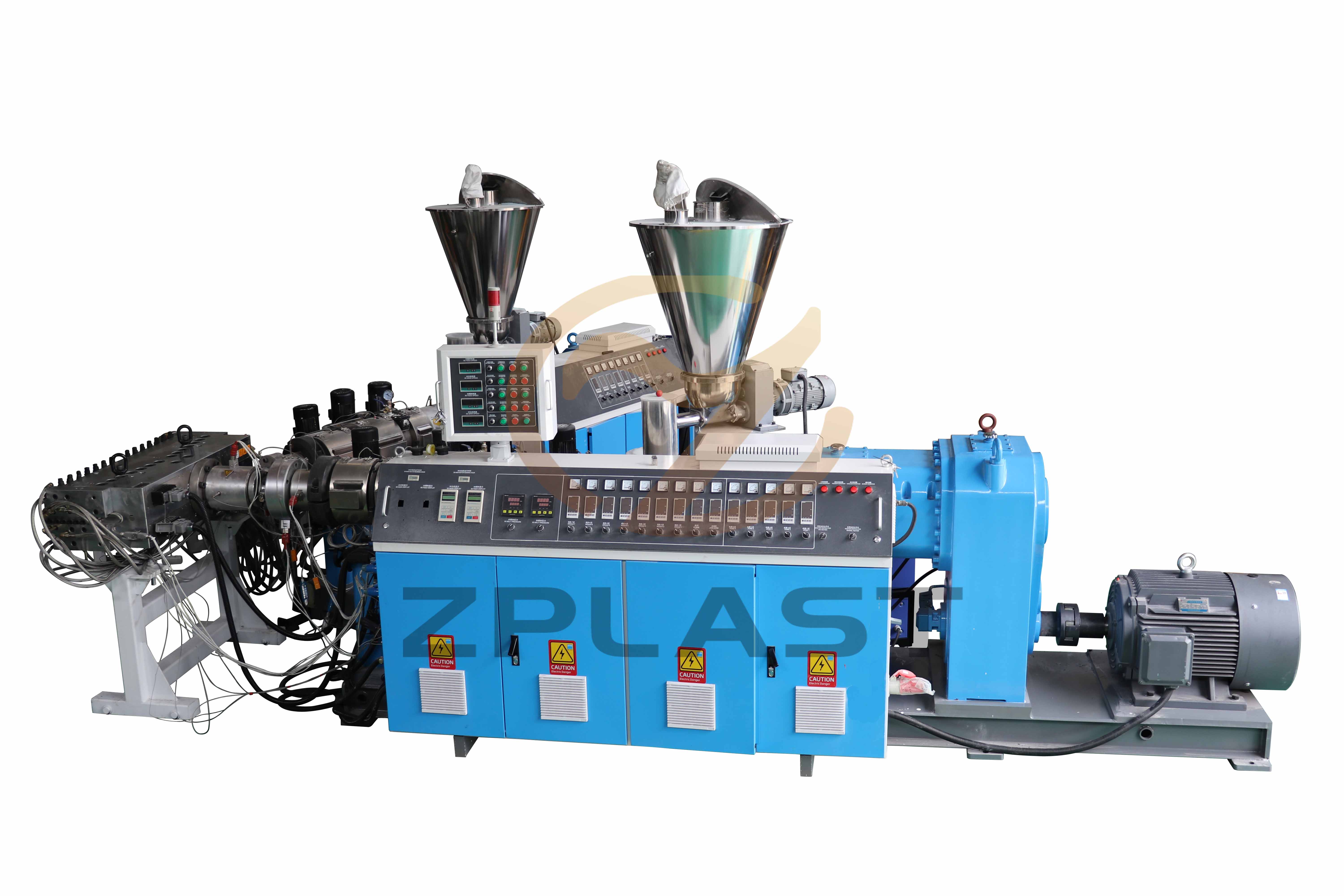

2. Extrusion System (Screw & Barrel)

Famous brand:

Screw diameter: ¢65mm 132mm

Max. designed output: 150 ~ 220 kg/h

PVC powder special designed for screw with rotation speed of 1 ~ 34.7 r/min

Screw material: 38CrMoAlA, nitrogen treatment, with the thickness: 0.5~0.7mm, hardness: HV740~940.

Screw core temperature controlling: cooling by circulation heat conduction oil.

Barrel material: 38CrMoAlA, nitrogen treatment, with the thickness: 0.6~0.7mm, hardness ≥HV940.

Heating unit: cast aluminium heater + stainless steel covering + cooling fan

Cooling unit: Fan with medium of air, supply precise temperature controlling

Heating zone quantity: 4 with total power 21kw Temperature range: 50~300℃

Blower fan power: 0.55kw/set (3 set)

3.Dosing feeding System

With stainless steal hopper and forced mixing unit

Feeding motor power: 0.75kw, 3 phase asynchronous motor

Controlled by Imported brand AC frequency converter

4.Vacuum exhaust system

Vacuum pump: 1 set

Vacuum pump power: 1.5 Kw

Vacuum degree: 0~ -0.075 Mpa

4.Transmission system

High torque output

Water cooling device

Teeth hardening, precision gear grind treatment.

Adopting Germany technology, with a long service life, low noise and low heating

Integrated vertical type gearbox, motor directly connected to gearbox

Distributor: Single screw torque output transfer to twin screw torque output by super conical gear wheel.

5.Main motor system

Main AC motor power: 37 kw , 380V, 50Hz

Main motor adjustment: by AC with imported brand

6.Dimension and weight

Outer size: 4200mm×1500mm×2100mm

Center height: 1050mm

Weight of extruder: 4000kg