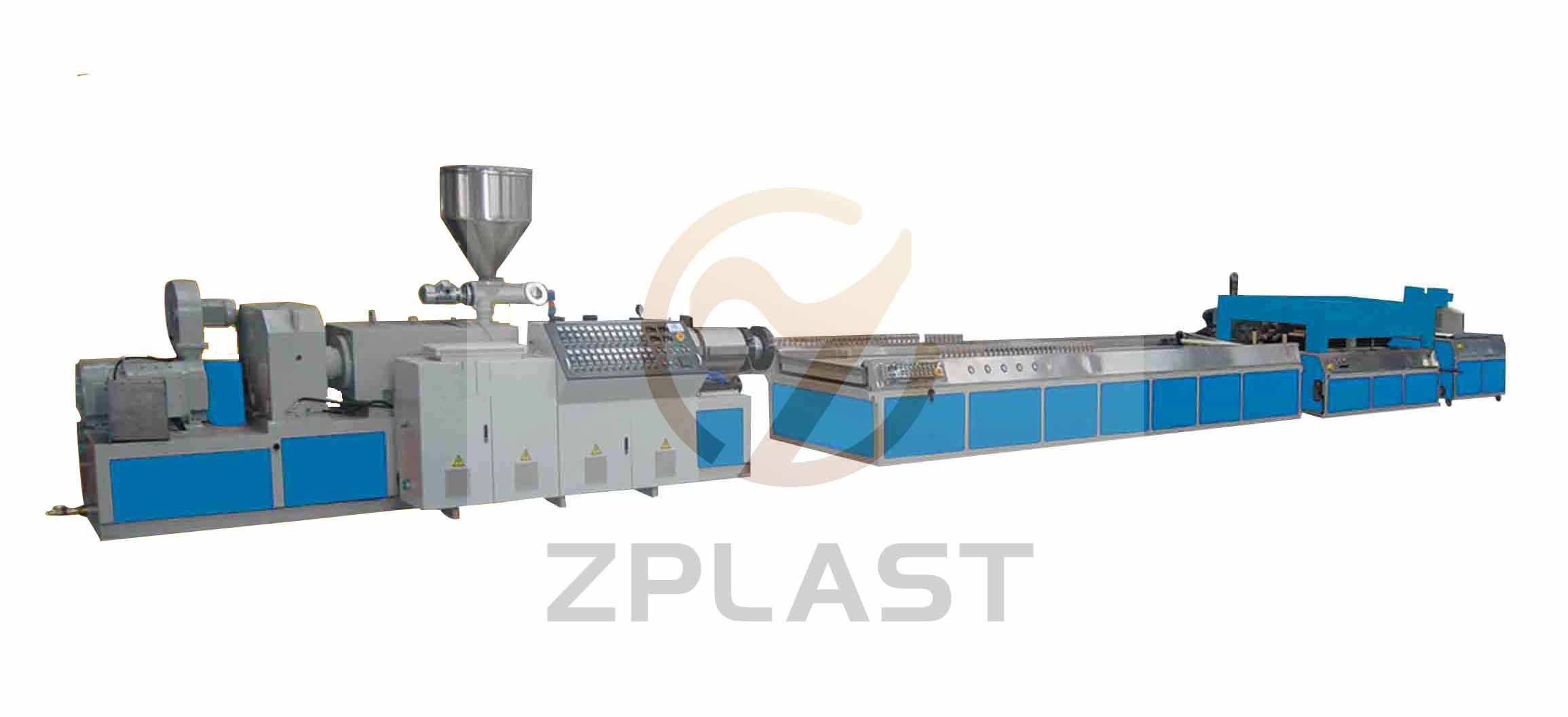

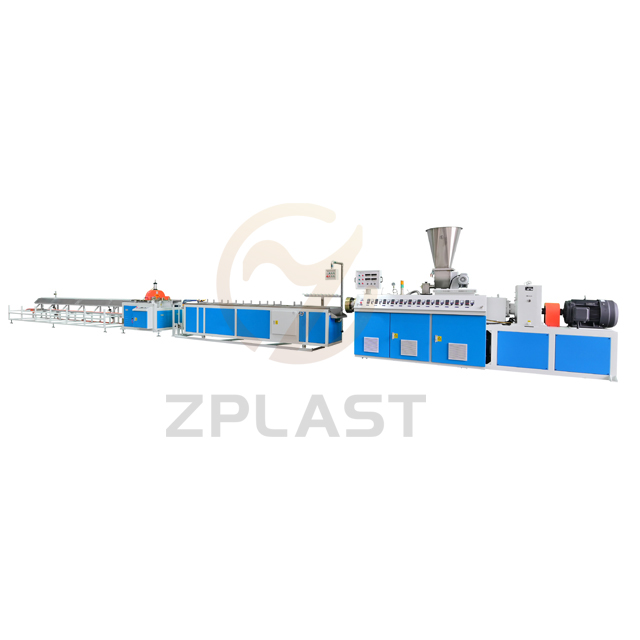

PVC wood plastic solid hollow foaming board panel extrusion producton line

Brand ZHUOTIAN

Product origin Shanghai

Delivery time 50-60

Supply capacity 30set/month

Structure of the PVC foamed board: Outer surface layer is rigid PVC and inner layer foamed PVC, it feature in low machine and formula cost compared with PVC skinned foamed plate, meanwhile, the product and parameters are all equal or better. Also, the surface of the product can be printed or laminated to get different patterns.

The PVC foam board extrusion line, PVC furniture board machine, PVC bathroom and kitchen cabinet board machine include: main extruder, co-extruder, distributor, calibrator mould, cooling rack, haul off, cutter and stacker.

Machine general information:

Suitable material | : PVC powder |

Finished product width | : 1220mm |

Product thickness | : 5-30mm |

Size of production line | : 30m x 3.5m |

Line output capacity | : 350kg/h |

Voltage standard | : 380V/3Ph/50Hz |

Installed power | : 350kw |

Real production power | : About 180-220kw |

Compressed air | : 0.6-0.8MPa |

Water temperature | : 10-15℃ |

Machine list:

1. SJZ80/156 conical twin screw extruder (with screw feeder) | 1 set |

2. 1320mm width PVC foam board (5-20mm) mould | 1 set |

3. Foam board mould temperature controller | 1 set |

4. Vacuum calibration table (with 4-group calibrators) | 1 set |

5. Cooling supporting frame | 1 set |

6. 8-group roller type haul-off unit (with protection film lamination device) | 1 set |

7. Longitudinal and transversal cutter | 1 set |

8. Dust suction device | 1 set |

9. Stacker | 1 set |

10. Electrical control cabinet | 1 set |