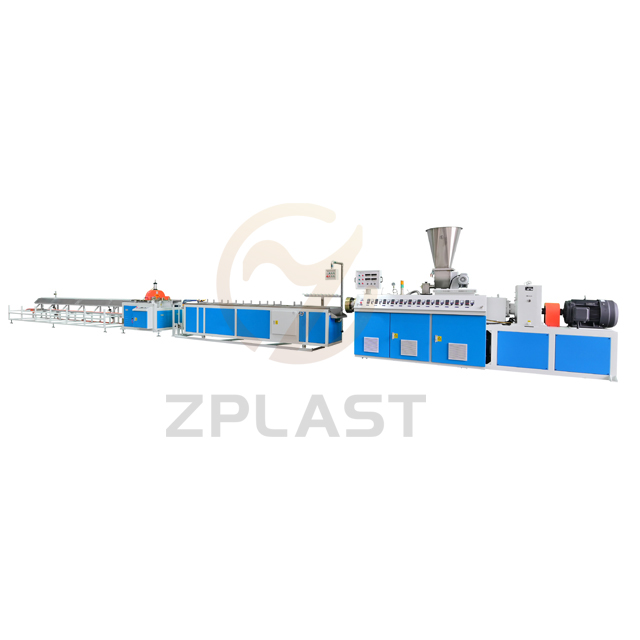

Pvc Sheet Pile Profile Production Line

Brand zhuoran

Product origin huangshi

Delivery time 60workdays

Supply capacity 60 set/year

1. the Pvc sheet pile Production Line can be used to produce pvc sheet pile

2. Pvc sheet pile Production Line mainly consists of a screw feeder, a conical twin-screw extruder, moulds, a vacuum setting table, a cutting machine, a stacker and some auxiliary machine (optional)

3. By changing different moulds, the same production line can be used to produce pvc hollow board with different size

work condition:

power: 3-phase, 380v+/- 10%, 50HZ

cooling water:< 20°C ,0.2~0.4 Mpa, ~8T/h

compressed air: 0.4~0.6 Mpa

main machinese of production line:

1 SJSZ 80/156 conical twin screw extruder

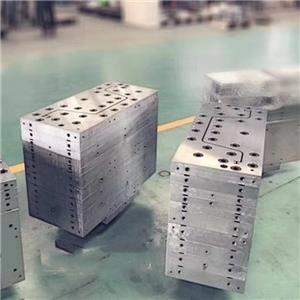

2 mould

3 calibration table

4 haul off machine

5 saw cutting machine

6 stacker

7 coextruder

specification :

A.SJSZ 80/156 CONICAL TWIN SCREW EXTRUDER

III. Detail specifications of machines | |

Items | Technical Parameters |

GSZ80/156 Extruder

| |

Extrusion capacity (kg/h) | 300-380kg/h |

Outer Size (mm) | 4750mmX1550mmX2460mm |

Total Weight (Kg) | 5000Kg |

Manufacture of the motors, pumps | The main motor: 55KW; Motor for feeder:1.5Kw |

heating zones | 12 heating zones for spare use for mould. |

2. Screw | |

Diameter (mm) | 80/156mm |

Effective length (mm) | 1815mm |

Quantity | 2 pieces |

The rotation speed(r/min) | 1~36.9 (Counter-rotating) |

Thickness of nitrided layer | 0.6~0.7 mm |

Suitable for powder material or not | Yes |

method | Screw feeder |

3. Barrel | |

Heating power (kW) | 36Kw(8/8/8/12) |

Temperature range(℃) | 50~300℃ |

Adapter | Stainless steel 3Cr13, chromium plated, with inner convergent flow type |

Cooling system | 4X0.55Kw Blower fans |

Quality Guarantee

| Testing block and tested report are available. Guaranteed period is more than 10000 working hours |

Thickness of nitrided layer | 0.6~0.7mm |

4. Calibrated feeding system定量给料系统 | |

Feeding method | Calibrated feeding |

Feeding screw’s rotation speed | 0.5~50r/min |

Motor power(kw) | 2.2KW |

Motor rotation speed | 10~1500r/min |

2. GYF600 vacuum calibration table

material | Calibration tanks and basin are made of stainless steel. |

Vacuum pump | two set , 7.5kw |

length of table | 6 meter |

Table width | 1.4 meter |

Material | calibration tanks and basin are made of stainless steel. |

Vacuum pump power and quantity | 7.5 KW x 2 sets 5.5kw x2 sets |

Vacuum degree | -0.09 Mpa |

Water pump power and quantity | 5.5 kw x 1 set |

YF 600 HAULING MACHINE

1 | Speed of Haul-off | 0.2-2m/min |

2 | Table length | 6000mm |

3 | Power | 1.5kw*2sets frequency control |

4 | Traction form | pneumatic |

YF 600 SAW CUTTING MACHINE

1 | Fixed length cutting,Fixed-length using autonics meter and the meter accuracy。 | |

2 | Max. cutting width | 600mm |

3 | working pressure | 0.5~0.7 Mpa |

4 | cutting power | 3.0kw |

YF 600stacker:4 meter

1 | Total length | 4m |

2 | Design for max width of product | 600mm |

3 | limited switch measuring length. | |

co extruder 55/28 single screw extruder:

1 | extrusion capacity | 35~55kg/h600mm |

2 | diameter of screw | 55 mm |

3 | L/D | 28:1 |

4 | driving motor power | 18.5kw |

5 | power: | 3P*380V*50Hz |